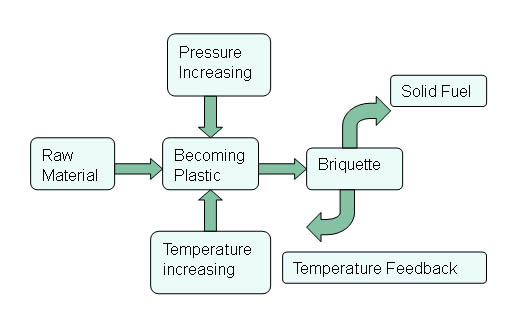

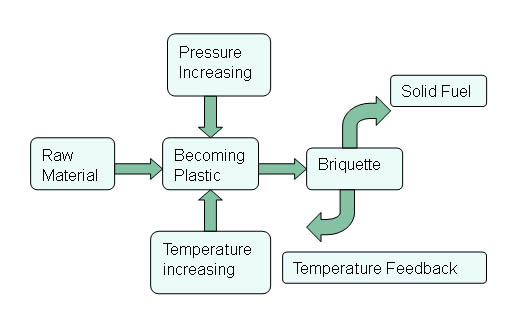

For those who don’t know, the charcoal briquette machine is used to suppress different types of mineral powders, metal powders, carbon powders and any other material to mold them. The three best characteristics of the machine are high density, high strength and harness. These properties are because of the mandatory rollers. The working principle of the charcoal briquette machine is that it passes the power to the pressure rollers with the help of reducer. The natural materials that enter into the rollers, high pressure of the rollers convert them to the finishing product. After long research and hard work, four roller machines have been developed.

These machines work on the same principle as that of two rollers machine. Two rollers suppress materials in the form of pipeline and a solid foundation has been developed for the finished ball. The specifications of the product include high forming output and rate, the pressure of the rollers is very high that squeeze the material in seconds and it has no smell or smoke coming out of the machine. These features enable the machine to use for domestic purposes and it has great demand in the international market. The high density feature makes it possible for the customer to squeeze any product and high pressure makes the work easy.

Posted in

Charcoal Briquette Machine at February 29th, 2012. .

This briquette machine is a new-style machine used to create fuel for home usage. The machine takes in the raw materials, pass it through the crusher or the hammer mill which crushes it. This crush wood is then passed through the drier which dries the material. The drier passes the material through biomass briquette machine, and the product prepares. The important thing about the raw material in the machine is its size. These machines are divided into two types to crush the material in two different sizes.

The choice of wood briquette machine model will depend on the size of the material and type of the raw material. The crush material in the wood crushing machine is used to crush the wood. The size that the wood crusher can process must be less than 200 mm diameter. Furthermore, note that the moisture of the wood must be less than 30%. After the wood pass from the crushing machine, its size reduces to 3-5mm, which is best for briquette and drying purpose. Another type of wood crushing machine is hammer mill. This type of machine is used to cut large materials like wood into small materials. This machine can only be used for soft materials like wood and corn cob.

Posted in

Wood Briquette Machine at February 29th, 2012. .

Straw briquette device is a new kind of new-style straw coal machine, which is available in the market at very low cost. The machine is renewable; environment protected and has the functioning of biomass cleaning. The straw briquette machine  is widely used in hotels, restaurants and industries where they perform coal boiler functioning and the save huge amount of fuel cost. The length of raw material that we can use in straw coal machine is between 2 mm to 90 mm. Moisture contents of the materials should be between 5% – 30%, and the shape of product must have a diameter between 6mm to 60mm. The energy parameters of the straw coal are 3500 Kcal to 5500Kcal.

is widely used in hotels, restaurants and industries where they perform coal boiler functioning and the save huge amount of fuel cost. The length of raw material that we can use in straw coal machine is between 2 mm to 90 mm. Moisture contents of the materials should be between 5% – 30%, and the shape of product must have a diameter between 6mm to 60mm. The energy parameters of the straw coal are 3500 Kcal to 5500Kcal.

The straw briquette machine is suitable for every material that has moisture contents less than 30%. The system of electric heating in the machine is automatic, and it adjusts itself according to the humidity of material so that problem of congestion may not come. The best thing about the machine is its simple structure, easy to operate functions, and automatic electric heating adjustment. The materials that are best for briquette machine include wood, straw, peanut, seed hulls and all other raw materials that are available to you. The thing that you should note while using the raw material is that it should not have moisture content of more than 30%.

Posted in

Straw Briquette Machine at February 29th, 2012. .

With the current world trend and economic state, a lot of people have gone through hardships especially when it comes to source of energy. Natural gas has gone high in price making it hard for people to purchase it. On the other hand, the other sources of energy have as well been increased in price. It is for this reason that a majority of people have resulted to making their own energy sources in order to save on their income. Biomass briquettes can be used as a source of energy. The best thing about it is that, the materials used to make it are inexpensive making it cost effective.

To make it possible though when making biomass briquettes, it is important for you to have a biomass briquetting press. This machine is important as it will ensure that all the briquettes that you need are ready in no time. This is as compared to a traditional machine that will take you several days or weeks before reaching the target of biomass briquettes that you need.

The best thing with a biomass briquetting machine is that, it has spare parts meaning that if it breaks down, you can make a replacement of the damaged part as soon as possible. Additionally, it comes with an affordable price meaning that you can purchase it and use it to make biomass briquettes without any hassle. Mind you, the press is readily available online and this means that you will not have to move from one place to the other finding it. you can even purchase the press directly from the comfort of your home.

Posted in

Biomass Briquetting Machines|Presses at February 27th, 2012. .

Biomass briquetting machine  is of much importance and it is important to put a lot of effort and seriousness when it comes to purchasing it. This is because these machines come in different colors, sizes, shapes and designs. As such, it is important for you to put your requirements into consideration first before making your final decision. There are some strategies that you can use in order to come up with a biomass briquetting machines that matches your needs and preferences just the way you want it.

is of much importance and it is important to put a lot of effort and seriousness when it comes to purchasing it. This is because these machines come in different colors, sizes, shapes and designs. As such, it is important for you to put your requirements into consideration first before making your final decision. There are some strategies that you can use in order to come up with a biomass briquetting machines that matches your needs and preferences just the way you want it.

Firstly, when buying this machine, it is important to consider its price. Since these machines are numerous, it simply means that the pricing will tend to differ as well. While this is the case, it is highly advisable for you to take time and do thorough research to come up with the best machine for your briquetting needs.

The other thing that you need to consider before buying a biomass briquetting machine is efficiency and reliability. There is no point at all of buying a machine that will not provide you with all the efficiency that you need. As such, consider how efficient and reliable the machine will be prior to making your purchase.

Look out for the product features that come with the machine. Remember, the features that the machine has will determine how efficient your briquetting will be. While this is the case, ensure that you have checked out all the features and you have known each function of the features. This in turn will make it worthwhile for you when it comes to biomass briquetting.

Posted in

Biomass Briquetting Machines|Presses at February 25th, 2012. .

is widely used in hotels, restaurants and industries where they perform coal boiler functioning and the save huge amount of fuel cost. The length of raw material that we can use in straw coal machine is between 2 mm to 90 mm. Moisture contents of the materials should be between 5% – 30%, and the shape of product must have a diameter between 6mm to 60mm. The energy parameters of the straw coal are 3500 Kcal to 5500Kcal.

is widely used in hotels, restaurants and industries where they perform coal boiler functioning and the save huge amount of fuel cost. The length of raw material that we can use in straw coal machine is between 2 mm to 90 mm. Moisture contents of the materials should be between 5% – 30%, and the shape of product must have a diameter between 6mm to 60mm. The energy parameters of the straw coal are 3500 Kcal to 5500Kcal.

is of much importance and it is important to put a lot of effort and seriousness when it comes to purchasing it. This is because these machines come in different colors, sizes, shapes and designs. As such, it is important for you to put your requirements into consideration first before making your final decision. There are some strategies that you can use in order to come up with a biomass briquetting machines that matches your needs and preferences just the way you want it.

is of much importance and it is important to put a lot of effort and seriousness when it comes to purchasing it. This is because these machines come in different colors, sizes, shapes and designs. As such, it is important for you to put your requirements into consideration first before making your final decision. There are some strategies that you can use in order to come up with a biomass briquetting machines that matches your needs and preferences just the way you want it.